JP Imbert's Topics:

Topic 1:

Interventions in tunnel boring machines: Designing the most difficult decompression tables

The tunnelling industry is developing around the world, as all the giant metropoles suffer from congestion and need tunnels for metro and highways. Tunnel boring machines have to pressurise their cutting chamber to avoid water flooding when digging under rivers or seas. When maintenance is required, workers enter the machine under pressure and need decompression procedures. Two options are available, bounce diving and saturation diving, but because of the costs, operators tend to push mixed gas bounce interventions to the equivalent of 60 msw. Tunnel tables are the most difficult tables to design. The work is intense, the heat is extreme, the environment is just mud and hydraulic oil but still the operation requires one to two hours continuous bottom time to perform useful work. The presentation details the various recipes (trimix specification, double gas switches, massive oxygen dose management,) and mathematical tools used to design such tables.

Topic 2:

From saturation diving to technical diving: Solving the mystery of gradient factors

The offshore industry works in saturation diving and projects constantly require deeper depths, higher excursions, intermediate decompression, etc. Algorithms constantly need to adapt to provide solutions and the lessons learnt from saturation diving can apply to technical diving. The first lesson is that decompression is a multiple stress. We went offshore monitoring divers and confirmed that bubbles are only one part of the problem: inflammation is present in all decompressions. When focussing on bubbles and the physical aspect of decompression, we learnt that saturation ascent rates show a discontinuity around 60 msw. The reverse engineering of saturation profiles has revealed that this discontinuity is related to bubbles appearing on the arterial side of the lungs. The lungs bubble filter transfer function is the critical factor for a safe decompression. We modelled this function and it provided corrections to established algorithms that are similar to ones provided by gradient factors. The presentation carefully unfolding the many steps of a decompression process and brings some scientific justifications to factors that has been always regarded as lousy empirical coefficients.

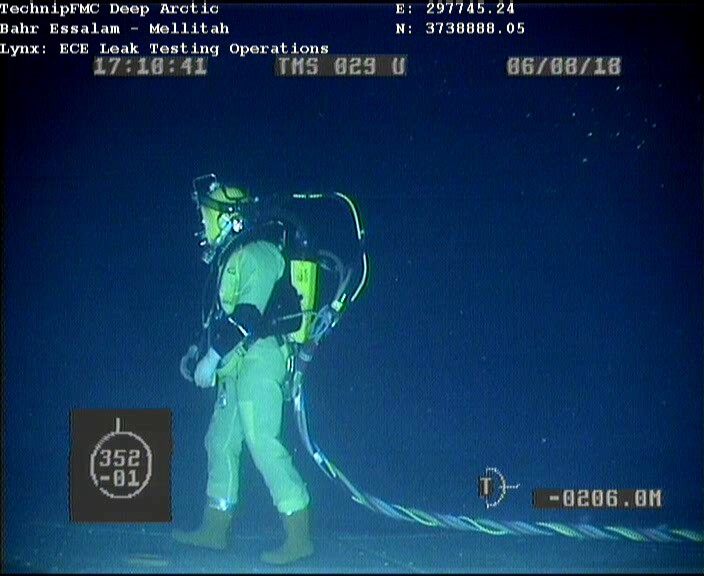

Jean-Pierre (JP) Imbert

Commercial Diver and Gas Decompression Modelling Expert

JP Imbert summarises his diving career as an ability to be there at the right place, at the right time. He started with Dr Lambertsen’s Predictive Study IV dive for a first encounter with isobaric counter diffusion. He continued at Comex as a research engineering, during the deep heliox and hydrogen programs that finally brought a man to 700m in a chamber.

During the 80’s, he was in Norway and in Brazil when the offshore industry developed deep saturation procedures to 300 msw.

Later, he started technical diving in France with IANTD and became a trimix and rebreather instructor.

During the last 20years, JP Imbert has worked as a diving consultant for large diving companies in the North Sea. A lot of the current commercial diving tables are his design.

He has been involved in several research programs on saturation decompression, HPNS monitoring and oxidative stress measurement. Recently, he has worked on the concept of a two-dimensional model for decompression tracking both the bubbles and the inflammation stresses.

JP Imbert admits he enjoys equations and decompression modelling and he is still pursuing the quest of the ultimate decompression algorithm.